As the application of optical modules becomes more and more widespread, the speed, packaging, power consumption and functions of optical modules are also developing in the direction of high speed, small size, low power and multi-function. Today we are going to talk about the DDM function in the optical module.

What is DDM?

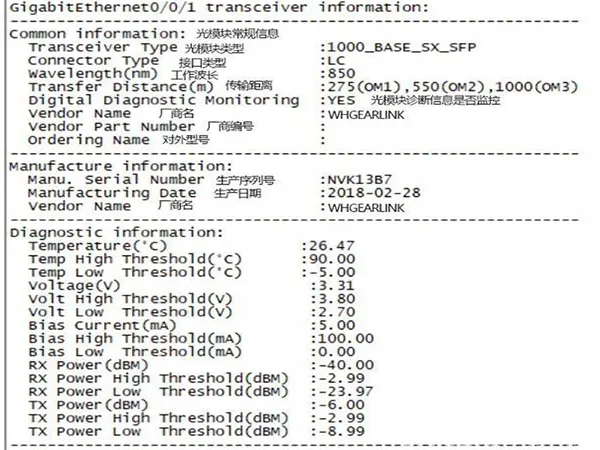

DDM (Digital Diagnostic Monitoring) digital diagnostic monitoring technology is a technology used in optical modules so that users can monitor the real-time parameters of optical modules. These parameters include working temperature, working voltage, working current, transmitting and receiving optical power, etc., and can also display the regular wavelength, speed, transmission distance, manufacturer name, appearance number, model, serial number, appearance date, alarm information, etc. of the module . Among the common optical modules today, only the electrical interface module does not have DDM information.

The DDM technology in the optical module provides a module performance monitoring method, which can help manage and predict the life of the module, locate system failures, and detect the compatibility of the module.

How to view DDM information?Use a console cable with an RJ45 connector on one end and a USB connector on the other. The USB connector is connected to the computer side, and the RJ45 connector is connected to the console of the switch. Open the terminal and enter the instructions of the corresponding equipment to view the DDM information of the optical module.

How to view DDM information?Use a console cable with an RJ45 connector on one end and a USB connector on the other. The USB connector is connected to the computer side, and the RJ45 connector is connected to the console of the switch. Open the terminal and enter the instructions of the corresponding equipment to view the DDM information of the optical module.

What is the role of digital diagnostic monitoring technology?

①Fault location

In the operation of optical services, failures are inevitable. DDM technology can help network managers quickly locate failures, reducing troubleshooting and repair time. Through the digital diagnosis function, it is necessary to conduct a comprehensive analysis of the warning status of the emitted optical power, received optical power, current, voltage, and temperature, so as to quickly locate and solve the problem.

②Compatibility test

Digital diagnosis can also verify the compatibility of the module. Compatibility verification is to analyze whether the working environment of the module complies with the data manual or is compatible with related standards. The performance of the module can only be guaranteed under this compatible working environment. In some cases, because the environmental parameters exceed the data manual or related standards, the performance of the module will decrease, resulting in transmission errors.

The working environment is not compatible with the module:

The voltage is out of the specified range

The received optical power is too high or too low

The temperature is out of the working temperature range